The Manufacturing Process

The Manufacturing Process

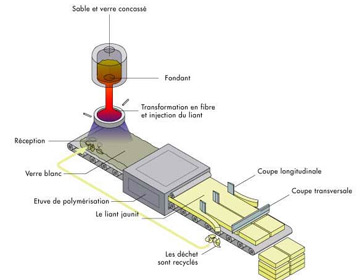

GRW Mineral wool manufactured from one of the earth's most abundant pumicd sedimentry diabase rocks. The rocks are graded and crushed to suitable size, mixed with required percentage Blast Furnace Slag and fluidities / fluxes, melted in a furnace at a temperature of about 1450°C.

The melt at a desired viscosity is directed into a fibrising unit to spin into finer Diameter wool. The wool coated with thermosetting binder are collected into a negative pressurized chamber in the forms Matts of desired density and thickness, compressed into various shapes & sizes.

The compressed mat for requires density & thickness passes through baking ovens, where the thermosetting binder is cured at accelerated temperature to maintain the required thickness. The finis product is cut into various shapes and sizes, laminated / stitched with facing materials as per customer's requirements standards for range of applications.